Have you ever wondered how your phone can capture the best moments of your life and how it connects you with the world? Thanks to the little piece of silicon that helps to make the microchip, a semiconductor that acts like the brain of your electronic devices.

Microchips are not rocket science, but they are definitely the foundation for rocket science. They are the tiny chips that power your automatic electrical vehicle system, give commands to launch spaceships, and more. Additionally, a component like RF Bandpass Filter is often integrated into microchips to ensure precise frequency selection in communication systems.

Microchips are the building blocks of today’s incredible advancements. But how do these tiny-looking chips take a journey from a conceptual idea to a reality that is capable of processing information at the speed of light?

So, get ready to unlock the secrets!

In this article, you will witness the incredible process of designing microchips from concept to reality that is shaping your future.

The Microchip Design Flow

Step 1: Designing the Chip’s Purpose

The very first step in the microchip design journey is all about understanding what the chip needs to do.

For example, a microchip designed for a fitness tracker will prioritize low power consumption to ensure a long battery life. This means the designers will choose specific electronic components and a microcontroller IC (a tiny computer on the chip) that are optimized for low-power usage.

Thus, the very first step in microchip design is the proper definition of requirements and the chip’s specifications. As an example, the designer will define what the purpose of the product is, how it will be used, and what specifications you need to satisfy.

Step 2: Architecture Definition

After understanding the purpose of the microchip design, the next step is the creation of the architecture. It should be done by considering the cost factor and power usage.

So, the designer makes a careful decision about choosing the architecture, like CISC or RISC, by carefully determining the pipeline structures, ALU numbers, cache size, and more.

Besides, if you want to know about FPGA and ASIC, you can check out this.

The architecture selection determines your microchip’s functionality; thus, the architecture is selected as per your needs. Subsequently, the designers record the structure within a Micro-Architectural Specification (MAS) to accurately predict power consumption and performance. A complete MAS guarantees that the design follows specifications and prevents mistakes, both of which are critical for achieving performance standards and timetables.

Step 3: Feature Design

The next process of microchip design includes functional and feature design. In this process, engineers try to define the functionality and required features of the chip.

For example, engineers will try to specify what functions the chip will perform and how it could interact with external devices by creating a high-level description of the requirements of the system and designing the algorithm to meet those criteria.

This step is important for defining the characteristics and capabilities of the microchip. During this feature design process, designers carefully and strategically plan, specify, and ensure the microchip meets the requirements.

Designers work closely with their customers to understand user needs and industry standards. They ensure the efficient design and development of the chip’s logic, which can eliminate any error that could occur in the final design process.

Step 4: Logic Design

The next and most important step in microchip design is logic design. In this step, the designers define the logical operations for microchip circuitry. The operation is implemented in such a way that the desired functionality is implemented.

It provides the actual circuit design and implementation. The process includes the creation of logical designs using HDL, which is a hardware description language. It includes designing the data paths, memory elements, control logic, and more.

Then the design is verified using the simulation tools and addressed for any potential issues or errors before moving on to the next step.

Step 5: Circuit Design

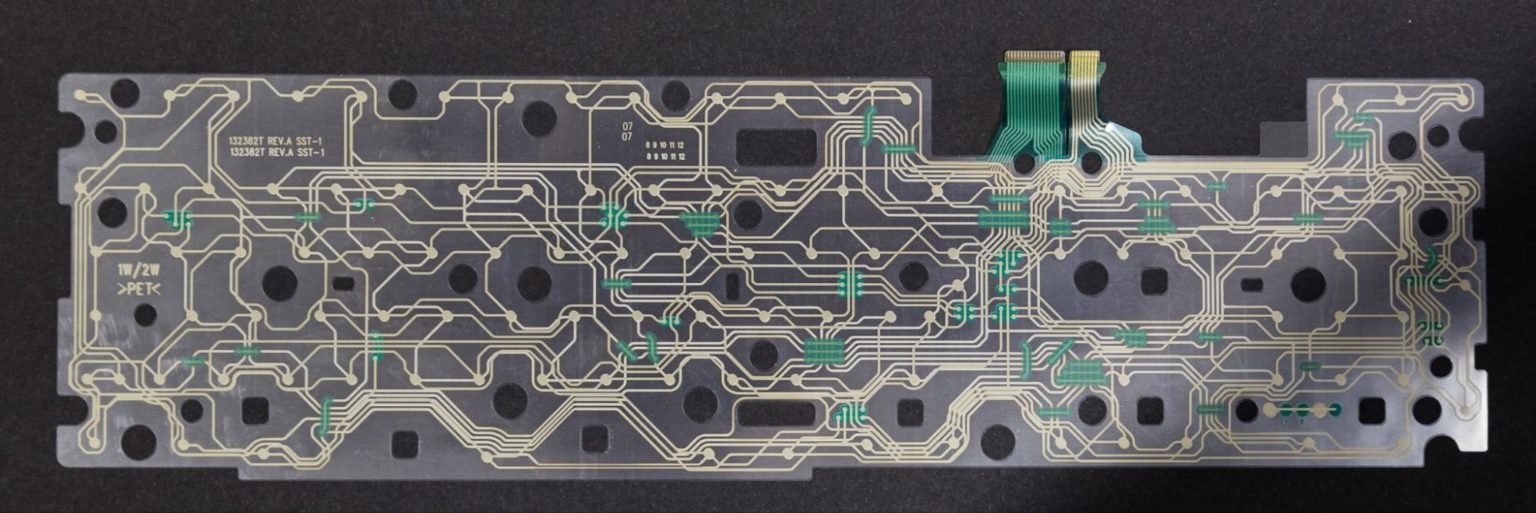

So, till now, designers have had the logical design of the microchip. So, the next step is the circuit design phase. During this circuit design process, the designer will transfer the logical design into the physical circuitry. It includes the process of selecting the electronic components—resistors, transistors, and capacitors.

These electronic components are carefully selected to meet the power, performance, and manufacturing requirements.

During the circuit design, stable operation is ensured with the design of the clock circuitry and power supply.

Designers create detailed schematics and layouts using CAD tools. They also simulate the circuit to ensure it performs well under various conditions. Engineers carefully plan the layout, thinking about things like how signals move, where power goes, and what can be made in manufacturing.

By carefully considering the physical circuit and electronic component selection, engineers ensure that the microchip fulfills performance objectives, functions repeatedly, and produces economic value.

Step 5: Physical Design

In the physical design phase, the engineer turns the idea of logical and circuit design into the actual layout of the microchip’s components. They place the electronic components strategically, ensuring the components take up as little space as possible. Engineers then check and identify any design-related issues.

In this process, the EDA software tool is used to verify the circuit design layout. Besides, the circuit is also verified through Layout Versus Schematic (LVS), or Design Rule Check (DRC). It ensures the design is correct for logical, electrical, and other required functionality.

Simulation and Verification

Once you finish designing your chip, it’s time to test it, which is called verification and validation (V&V). This means putting the chip through different tests using special tools to make sure it works as intended and meets all the requirements.

If there are any mistakes in the design, they’ll show up during this testing phase. Validation also helps check if a few samples of the chip, called prototypes, work correctly.

Finally, there’s the fabrication step, where the physical layout design is turned into reality. Once the chip design is complete and verified, a file called a GDS file is sent to a manufacturing facility called a foundry to make the chip.

Conclusion

The microchip design process is a complex and challenging task, and it includes various steps. Each step requires careful planning and design to reduce the possibility of error in the future. There are various types of chips on the market, and with technology, these are becoming more and more optimized.

Thus, the journey of microchips from concept to reality is amazing. It plays a crucial role in shaping technology.

Microchip designers make high-tech technology available to millions. They do it by working together, coming up with new ideas, and focusing on the little things. They do this by pushing growth and innovation in many fields.

As we figure out how to make microchips, we learn about the complex processes. They make the change possible. These processes will shape the future of our connected world.

If you are having trouble finding the right electronic components, including microchips, then check out PartStack. With just one click, you can find the required electronic components in no time. Feel free to check out the catalog section to explore more.