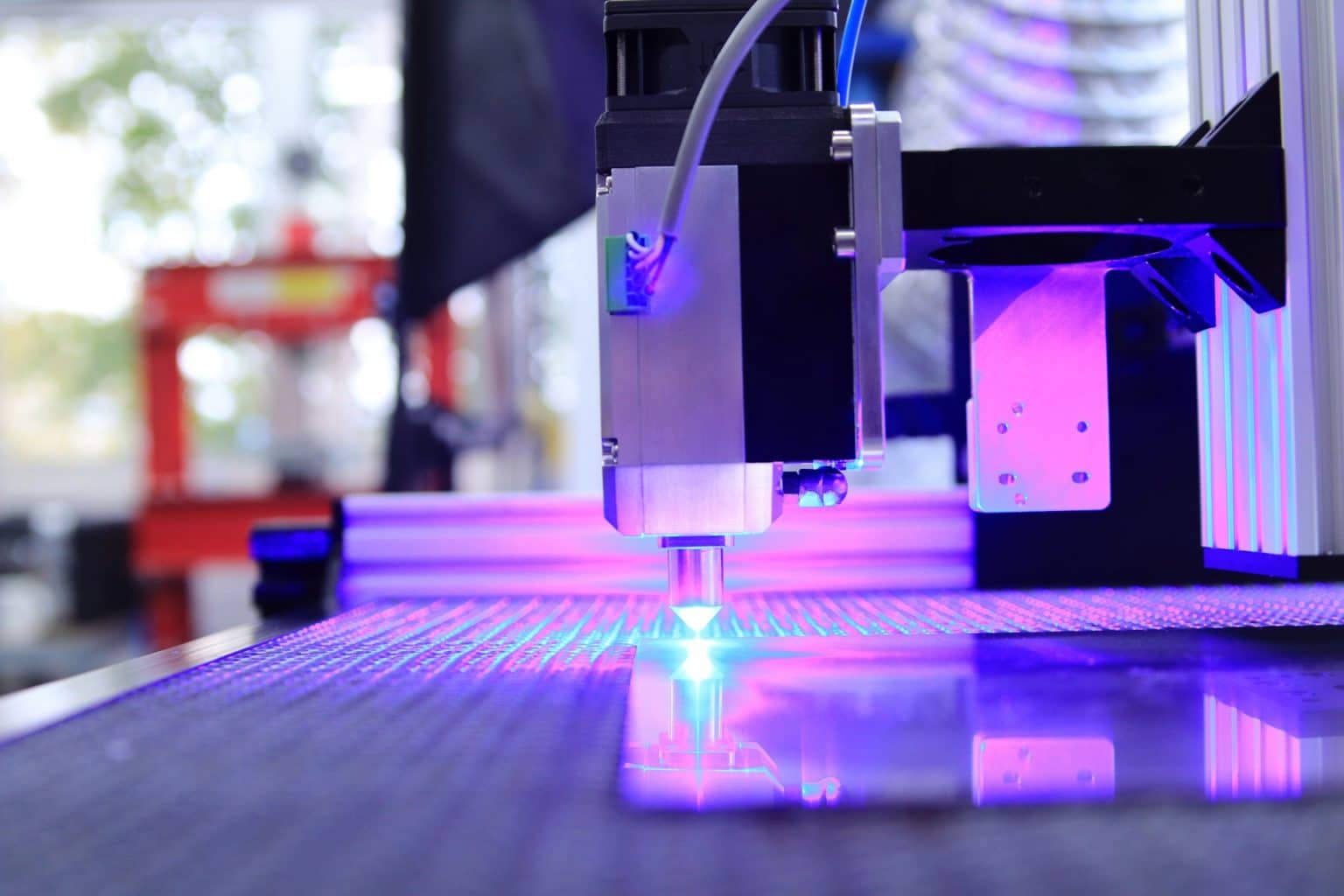

Laser cutters applications span various industries, from intricate metalwork in aerospace to crafting personalized wooden signs. In recent years, Home laser cutters have become hot and popular, meaning more people can buy them and enjoy laser cutting. While their versatility is enticing, careful consideration is crucial before purchasing. Analyzing your needs, budget, and technical specifications like laser power and bed size ensures you select the laser cutter that perfectly aligns with your project requirements and ensures a successful and safe experience. This article will tell you the important things you need to know before buying a laser cutter.

6 considerations before buying a laser machine

Budget and price

Laser cutters prices vary from a few hundred to several thousand dollars. Considering the input budget is usually inextricably linked to the purpose, you need to consider beforehand such as what you will use the laser cutter for. Hobby projects, small business, or professional use. Take your budget and compare it to the prices of different models of laser cutting machines. Normally, blue lasers are the cheapest, while fiber lasers can cost over $10,000.

Portability and flexibility

As for general ranges, desktop laser cutters are about 610mm x 610mm (24″ x 24″) with a working area of 400mm x 400mm (15.75″ x 15.75″). They are lightweight (~5kg) and portable. Larger CO2 and fiber lasers may require special equipment or multiple people to move and won’t fit through standard door frames.

Considering the different scenarios of use, it may be necessary to take into account the option of acquiring a machine with sufficient portability and flexibility. Some manufacturers will have a selection of models, such as the xTool F1.

Extensions and accessories

Laser cutter extensions and accessories play a vital role in enhancing the functionality, safety, and overall user experience of your laser cutter. In order to enhance the functionality of the laser cutter and to create more play, brands that don’t provide extensions/accessories should be avoided.

Expanded Capabilities includes:

- Different cutting and engraving options: Rotary attachments allow for engraving on cylindrical objects like mugs and bottles. Honeycomb cutting beds provide better support for delicate materials like fabric or thin wood, preventing warping. Air assist nozzles can improve cutting quality for specific materials.

- Material Handling: Material feeders ensure continuous cutting of long sheets, boosting productivity. Exhaust improvers like downdraft tables enhance fume extraction for specific materials, leading to a cleaner workspace.

Improved Safety and Efficiency:

- Fume extraction and filtration systems: These are crucial for removing harmful fumes and dust generated during cutting, ensuring a safe working environment.

- Cooling systems: Water chillers help regulate the laser’s temperature, maintaining optimal performance and preventing overheating.

- Lid extensions and enclosures: These improve safety by minimizing laser beam exposure during operation.

Laser types and materials Compatibility:

Material compatibility is a crucial aspect to consider before purchasing a laser cutter. Materials absorb these wavelengths at varying degrees, affecting cutting efficiency.

Commonly Cuttable Materials:

- Woods: Plywood, acrylic, balsa wood, and hardwoods (with adjustments) are popular choices for laser cutting due to their clean cuts and versatility.

- Plastics: Acrylic, PETG, and some ABS plastics are suitable for laser cutting, offering transparency or vibrant colors for projects. However, some plastics may melt or release harmful fumes, requiring research for safe options.

- Fabrics: Fabrics like felt, leather, and some synthetic materials can be laser cut for intricate designs. However, flammability is a concern, and proper ventilation and material selection are crucial.

- Paper & Cardboard: Laser cutters excel at precise cuts for paper crafts, invitations, and packaging. Thicker cardboard requires adjustments to avoid burning.

- Metals: While CO2 lasers can etch some coated or anodized metals, fiber lasers are typically used for cutting through thin sheets of steel, aluminum, and other metals.

Software Compatibility:

Consider the included software and its ease of use. You can unlock additional features like advanced nesting algorithms for material optimization and improved cutting efficiency.

Types of Laser Cutting Software:

- Proprietary Software: Many laser cutter manufacturers offer their own dedicated software for controlling the machine. These programs are often user-friendly and optimized for the specific capabilities of their machines. However, they may limit compatibility with other design software you might already use.

- Third-Party Software: Popular options like RDWorks, LightBurn, and LaserWeb offer broader compatibility with various laser cutter models. These programs often provide more advanced features for design manipulation and laser control. However, they might require a learning curve and may not offer the same level of integration with specific laser cutter functions compared to proprietary software.

Including considerations

- File Compatibility: Ensure the software supports the file formats you typically use for your designs (e.g., DXF, SVG, AI).

- Learning Curve: Evaluate the software’s ease of use and available tutorials or support resources.

- Features: Consider the features important to your workflow. These might include:

- Design tools for creating or editing vector graphics.

- Nesting algorithms to optimize material usage.

- Laser path editing and power control for intricate projects.

- Layer control for defining different cutting depths or speeds for specific elements in your design.

- Integration with Design Software: If you use design software like Adobe Illustrator or CorelDraw, some laser cutting software offers plugins for direct file export with cutting parameters. This can streamline your workflow significantly.

Learning curve

Laser cutters offer incredible creative potential, but there’s definitely a learning curve to mastering their operation. Depending on your situation from these factors, you can choose the right machine for you

- Your Experience Level: If you’re new to designing software and laser cutting in general, expect a steeper initial learning curve.

- Machine Complexity: Simpler laser cutters with basic controls might be easier to pick up initially. More advanced machines with extensive features may require more time to learn and master.

- Software Interface: User-friendly software with clear instructions and readily available tutorials will significantly ease the learning process.

Conclusion

From application needs and material compatibility to software compatibility and safety features, a well-informed decision ensures you get the perfect laser cutter for your projects. Ready to take the plunge? Research reputable laser cutter retailers and explore online communities for further guidance. With the right knowledge and a dash of creativity, your laser cutter can become a valuable asset for bringing your ideas to life.